Heat Exchangers (Main)

-

In Stock

Alpha Boiler Main Heat Exchanger 1.031448

£126.50 Exc. VAT £105.42 Add to cart -

In Stock

Alpha Boiler Primary Heat Exchanger 6.5632470A

£107.71 Exc. VAT £89.76 Add to cart -

In Stock

Alpha CD 30S CD 32C Boiler Main Heat Exchanger 1.018593

£145.20 Exc. VAT £121.00 Add to cart -

In Stock

Alpha Condensing Heat Exchanger 3.015063

£62.70 Exc. VAT £52.25 Add to cart -

In Stock

Alpha PRI / COND Boiler Main Heat Exchanger 1.018593

£330.00 Exc. VAT £275.00 Add to cart -

Out of Stock

Ariston Boiler Main Heat Exchanger (30KW) 65111606

£143.00 Exc. VAT £119.17 Add to cart -

Out of Stock

Ariston Chaffoteaux Primary Heat Exchanger 61010017

£217.80 Exc. VAT £181.50 Add to cart -

Out of Stock

Ariston Main Heat Exchanger 65111608

£195.00 Exc. VAT £162.50 Add to cart -

Out of Stock

Ariston Main Heat Exchanger 998138

£87.12 Exc. VAT £72.60 Add to cart -

In Stock

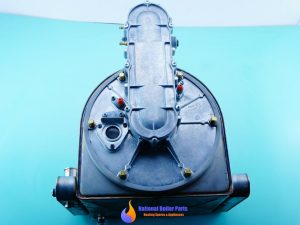

Baxi / Potterton Boiler Main Heat Exchanger 5114687

£52.24 Exc. VAT £43.53 Add to cart -

In Stock

Baxi / Potterton Boiler Main Heat Exchanger 5114687 Type 2

£50.00 – £330.00 Select Options This product has multiple variants. The options may be chosen on the product page -

Out of Stock

Baxi Duo-Tec Combi Main Heat Exchanger 5114688

£129.99 Exc. VAT £108.33 Add to cart