Condensate Traps

-

Out of Stock

Baxi Boiler Condensate Trap 5111451

£36.96 Exc. VAT £30.80 Add to cart -

In Stock

Baxi Boiler Condensate Trap Assembly 5111978

£36.96 Exc. VAT £30.80 Add to cart -

Out of Stock

Baxi Condensate Trap Kit 7213570

£46.20 Exc. VAT £38.50 Add to cart -

In Stock

Baxi Main Potterton Condensate Trap 5111978

£15.60 – £39.60 Select Options This product has multiple variants. The options may be chosen on the product page -

In Stock

Baxi Potterton Main Condensate Trap 5111714

£42.22 – £46.20 Select Options This product has multiple variants. The options may be chosen on the product page -

In Stock

Heatline Boiler Condense Trap 3000000010

£38.19 Exc. VAT £31.83 Add to cart -

Out of Stock

Ideal Boiler Siphon Trap 175583

£14.40 – £26.88 Select Options This product has multiple variants. The options may be chosen on the product page -

Out of Stock

Ideal Condensate Trap 174244

£15.18 Exc. VAT £12.65 Add to cart -

Out of Stock

Ideal Condensate Trap Seal Kit 174244

£35.94 Exc. VAT £29.95 Add to cart -

In Stock

Potterton Promax System Plus A Condense Trap Plug 5118972

£7.50 Exc. VAT £6.25 Add to cart -

Out of Stock

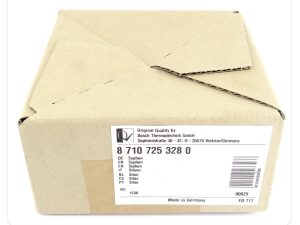

Worcester Condensate Trap Syphon 87107253280

£44.44 Exc. VAT £37.03 Add to cart