A diverter valve is an important part of any heating system. It usually operates out of sight to allow the boiler to provide heat to multiple parts of a property. However, those with an overhead shower bath will have seen how diverter valves work first-hand. Loss of boiler valve functionality can leave someone without central heating, hot tap water, or both.

In this blog, we’ll discuss how a diverter valve in a boiler works, what diverter valves issues look like, and how they can be resolved.

Diverter valves

Diverter valves are important parts that control the flow of hot water and gases. This can be a vital function in many heating and cooling systems, not just in boilers. Diverter valves can also be found in:

- Motor vehicles

- Showers

- Industrial machinery

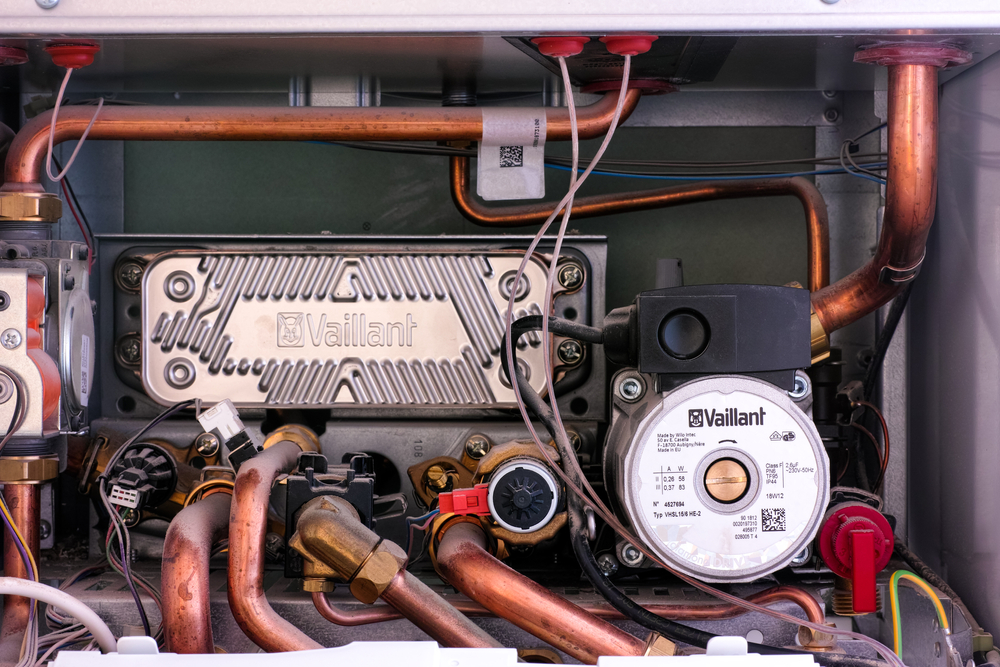

The appearance of a diverter valve will vary across brands and industries. However, most feature multiple inlets with a lever, pin, or other kind of control mechanism. Diverter valves can also use a range of materials such as aluminium, stainless steel, carbon steel, and plastic. They are typically located at easily accessible positions within the appliance so that any issues can be easily resolved.

How a boiler diverter valve works

In a boiler, once the water has been heated, the diverter valve is responsible for directing it to different areas around the property. This includes systems that are supplied by hot water, such as radiators, taps, and showers. For example, if you were to turn the tap on when the central heating is on, the hot water supply will be temporarily diverted away from the latter.

Diverter valves are not present in regular home boilers and heating systems. Instead, they are exclusively a combi boiler feature. The valve will open and close depending on where the hot water supply is demanded. When water is required for your home’s central heating system, the diverter valve will send water from the boiler’s primary heat exchanger. If it needs to supply taps or showers, water will be directed to the plate heat exchanger first.

Read our blog ‘What is a heat exchanger in a boiler?‘.

Common diverter valve problems

All boiler parts, including diverter valves, are susceptible to wear, degradation and eventual breakage. A diverter valve is an important boiler part as it’s responsible for the efficient assigning of hot water throughout residential properties. As such, when issues arise it’s useful to have a quick option for accessing spares like NBS. People often notice a problem with their boiler diverter valve when the following symptoms start appearing.

Loss of temperature

If you notice that your taps are only producing lukewarm water, even when turned to the highest temperature, there could be an issue with your boiler’s diverter valve. Most often, this is due to the valve getting stuck and not allowing as much water through as it should be.

While the boiler is functioning in its heating of the water, it’s losing efficiency as the hot water isn’t being allocated correctly. As a result, this issue can lead to inflated gas and water bills.

Lack of central heating

As with the above problem, this is likely caused by a stuck diverter valve. In this case though, it will be stuck in the position that supplies hot water to taps and other outlets. This prevents hot water from getting to radiators and heating the building itself. It’s entirely possible for this to be reversed, with the property having no hot running water but central heating.

No hot water

A faulty or defective boiler diverter valve can be the cause of more severe boiler problems. These can include the build-up of magnetic sludge, increased limescale, or leaks. If hot water isn’t coming out of the taps, and the central heating isn’t effective, it could stem from a damaged or faulty boiler diverter valve It can also result in hot water only being available when the central heating is turned on.

The cost of fixing or replacing a diverter valve can be high. However, it’s always going to cheaper than replacing your entire boiler. Especially if you source diverter valves from a competitive supplier like NBS.

Fixing a boiler diverter valve

The above diverter valve problems need to be resolved quickly if proper heating is to be restored to the home. In the most severe cases, the valve issue must be addressed to prevent further damage to the boiler.

Although the boiler diverter valve will often be accessible through the panel on the back or underside of the appliance, it’s recommended to have a qualified heating engineer come to fix the issue. They can assess whether the diverter valve is the cause of the problem and if so, provide a solution.

Sometimes it’s a simple case of cleaning the part and the surrounding area to ensure proper function. Other times, it’s best to replace the diverter valve. It’s a hard-working part and oftentimes the valve won’t outlast the boiler system as a whole. Therefore, sourcing diverter valve spares can improve the lifespan of a home’s boiler.

Diverter valve boiler parts

National Boiler Spares are proud members of the Heating Trade Supplies Group. We’re leading re-manufacturers of boiler spares, providing vital services to professionals and homeowners. Our range of parts can allow boiler repairs to solve many different issues, regardless of make, model, and age.

Contact us today.